Anti-Static & Fire Retardant Foam for Military Applications

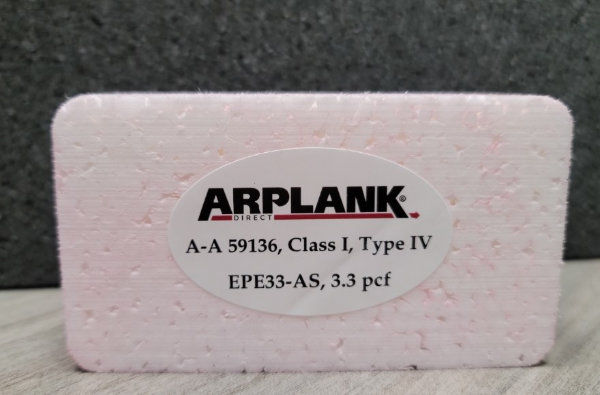

ARPLANK Direct foam products have been used by the US Military for protective packaging applications and military components since 2004. Our very durable, flexible, 6” solid materials come in low, medium, and high density for Type I, III, IV, and V in both Class 1 and Class 2 (Grade A). Grade B Anti-Stat (AS) and Grade C Fire Retardant (FR) materials are also available. All our closed-cell expanded bead foam planks meet Mil-spec CID-A-A-59136, CID-A-A-59135, and PPP-1752-D requirements.

- Fire retardant—meets UL94, ASTM E162, and ASTM 5132

- All grades pass FMVSS-302 and ASTM D5132

- EPE white can be made pink with Staticide #2002 (with a pink additive in the spray) to meet Military Specifications B-81705, Federal Test Standard 101B, and Method 4046

Our foam planks are mechanically expanded and thermally bonded together during manufacturing to form a solid 6” isotropic plank product that performs equally in all compressive and impact directions. The uniform cell size, wall thickness, and density make for easier fabrication, unlike extruded PE foams.

ARPLANK Direct EPE and EP products can be used as cushions for everything from fragile electronics components and optics to large, heavy containerized military ordnance and equipment. The service temperature range is from -76° F to 212° F, making them dependable in a large range of challenging applications.

Charcoal FR (CH-FR) – Left

Standard FR (Black) – Right

ARPAK EPE and ARPRO EPP Advantages for Military Applications

- Berry compliant – made in the U.S.A.

- 6” Solid x 48” X 72” – less layering and build-ups, less bonding, and better dimensional stability

- Fire Retardant—meets UL94, ASTM E162, and ASTM 5132

- Zero LEL meets and exceeds, < 10% LEL for closed containers

- EPP (SD) Static Dissipative for (Class 2, Type IV and V)

- All grades pass FMVSS-302, FR requirements

- Good vibration attenuation properties

- Low compression set and fast recovery time

- Non-abrasive – very low coefficient of friction

- Non-staining, non-corrosive

- Very high water and chemical resistance

- ARPLANK Direct EPE and EPP products are 6” x 48” x 72” and come in densities ranging from #2.2 to #9.0 PE and #2.0 to #6.0 crosslink PE, and equivalents.

- Unlike extruded foams, EPE can be fabricated regardless of orientation, resulting in better yields

- Per CID-A-A-59136, section 3.7 Density, 5.4.2, density may not be used to reject material

- ARPLANK materials never need to take exception to CID-A-A 59136, compression creep, and dynamic cushioning because of their superior physical properties

- No ARPLANK products need to take exception to CID-A-A-59136 dynamic cushioning 5.6.2 or compressive creep requirements like some chemical crosslink PE foams

- Anti-Static (White) can be made pink with Staticide #2002 spray to meet Military Specifications B-81705, Federal Test Standard 101B, and Method 4046

- R4 thermal insulation

Military Applications

Protective Foam for Military Products and Logistics

Shipping and storing and handling requirements

Case inserts for military electronics and hardware

Missile cradles & dunnage

Cushioning, packaging, and product protection for military parts

Ballistic and armor composite cores

Blast mitigation composites for MRAP vehicles

Arplank Foam Meets The Following Military Foam Specifications & Standards

- MIL STD CID-A-A59136, MIL STD CID-A-A-59135

- PPP-1752-D, Superseded by MIL STD A-A-59136

- FR – UL94, ASTM E162 and ASTM 5132

- Coast Guard 33 CFR 183.114

- Coast Guard Standard CGD-77-175

Foam Materials Strength & Stiffness Rankings

(from highest to lowest)

- Expanded Polypropylene (EPP)

- Expanded Polyethylene (EPE) Linear Low-Density Polyethylene (LLDPE)

- Low Density Polyethylene (PE LDPE)

- Cross-linked Polyethylene (XLPE) Ethylene Vinyl Acetate (EVA)

ARPLANK products offer better stiffness to weight ratio and lower densities (with the same performance) when compared to Extruded and Crosslinked PE foams.

Fire-Retardant Foam Options

ARPLANK EPE and EPP foam are produced with inert gas blowing agents, do not contain VOC’s, and are also free of CFC’s and HCFC’s. They meet military (MIL STD CID A-A-59136) criteria, Grade C (FR) in Type I, III, IV, and V fire retardant, per the procuring activity. This makes them ideal for packaging and product applications in the military space.

| Compression Strength (psi) | ||||

|---|---|---|---|---|

| Type I | Type III | Type IV | Type V | |

| TYP Value - Lower | 4 | 13 | 21 | 51 |

| TYP Value - Upper | 12 | 20 | 50 | 100 |

| 1.3 pcf EPE | 8 | |||

| 1.5 pcf EPE | 10 | |||

| 1.9 PCF EPE | 13 | |||

| 2.3 pcf EPE | 17 | |||

| 2.8 PCF EPE | 21 | |||

| 3.3 PCF EPE | 25 | |||

| 4.2 pcf EPE | 36 | |||

| 4.6 pcf EPE | 43 | |||

| 5.0 pcf EPE | 53 | |||

Have a Specific Application In Mind? Need a Material Sample?

We’re Here to Help. Get in Touch with Our Team Today.

I have worked with Chris Harrod for several years now on Military Missile Container programs. Chris is very knowledgeable on MIL specifications in general, Mil spec foam materials, and foam fabrication processes and capabilities. Chris makes my job easier with his responsiveness, attention to detail, and industry expertise. All in all, he is just a pleasure to work with on my requirements.

Brent Brooks

Logistics Management Specialist, Letterkenny Munitions Center