PRODUCT

Protective EPP and EPE Foam for Product Shipping and Storage

ARPLANK Direct beaded foam planks are the ideal solution for a large variety of product protection and packaging needs. Since EPP and EPE foam is lightweight, durable, and customizable, they are an affordable, environmentally sound, and sustainable way to protect a wide variety of products, whether they are being shipped or stored.

Why Use EPP and EPE Foam for Shipping and Storage?

- Outstanding cell-to-cell and bead-to-bead crush resilience for excellent recovery properties that will not lose cushioning protection. Developed for difficult repetitive-drop energy management.

- Low abrasion: excellent surface protection that will not mar or scratch high-gloss metals and plastics, glass, chrome, or powder coated products.

- Lower density: superior physical properties allow less foam to be used, reducing the cube size and lowering your shipping costs and carbon footprint.

- Thermal insulation: protect climate-controlled products and maintain temperatures during shipping. Ideal for durable returnable cold-chain shipping containers.

Product Protection

Shipping, Crating, Case Inserts, & More

From protective packaging and dunnage to industrial lighting and fans, heavy crate bases with computer rack systems, case inserts, and so much more, EPP and EPE foams are used in a variety of product protection applications:

EV Battery Pads & Wraps

Load Stabilizers

Military Ordnance

Packaging & Cushioning

Blocking & Bracing

Floater Pallets, Cushion Skids

Interior Automotive Components

Returnable Totes

Crate Liners

Interplant Dunnage

Part Separation and Shipment

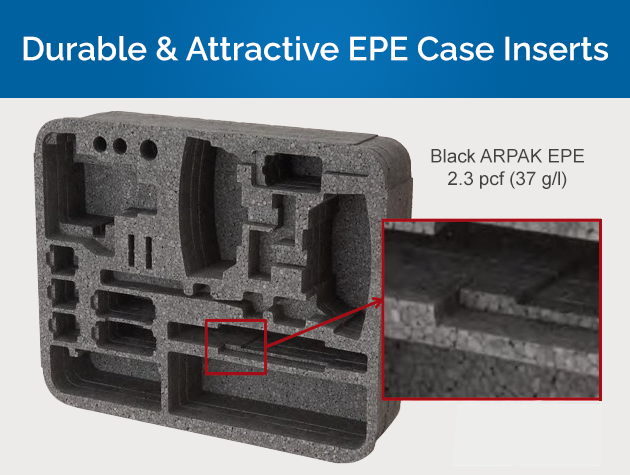

Lightweight & Durable Case Inserts

Class A Surface Protection

Expendable & Returnable Dunnage

Handheld Totes

Advantages of EPE Foam

- Excellent crush resistance and impact recovery properties

- Broader cushioning range to maximum designs and material yields

- Excellent elasticity, flexibility, and tensile and tear strength

- Stiffer at lower densities for more structural integrity than equivalent foams

- Very low coefficient of friction for highly finished surface protection

- Fabricates cleaner because it is more uniform for better part fit and function

- 50% better thermal expansion (CLTE) properties after cutting for tighter dimensional stability

Advantages of EPP Foam

- Best weight-to-performance ratios and dynamic cushioning

- New, more flexible EPP formulations are easier to fabricate

- High static loading range and very predictable foam set and creep properties

- Higher service temperature rating of up to 212F

- Chemical resistance

- Lightweight: cube and mass reduction

- Environmentally sound with cradle-to-grave recyclability

Anti-Static Foam Options

ARPLANK Direct’s anti-static (ESD) foam planks are ideal for the packaging and protection of electronic devices and other static-sensitive equipment. ARPLANK Anti-Static materials have a longer shelf life than extruded PE foams, and EPP Static Dissipative (SD) foams are also available from #1.9- #3.7 densities for permanent ESD protection.

Have a Specific Application In Mind? Need a Material Sample?

We’re Here to Help. Get in Touch with Our Team Today.

We began using Arplank EPE and EPP in our most sophisticated reusable crate designs due to its superior performance for shock and vibration protection over a wide loading range, and relative lack of creep. These designs hold heavy, very high value products, and Arplank is both tested to perform and does so in practice. We’ve been very happy with it and specify it globally. In addition, we’ve found the Arplank team very easy to work with, and always helpful when we need technical information or support.

CEO, International Packaging & Crating Company