The Materials You Need. The Service You Deserve.

As the leading supplier of high-quality expanded polyethylene (EPE) and expanded polypropylene (EPP) foam planks, ARPLANK Direct has the products and expertise you need to complete, protect, and ship your products without damage.

We have serviced foam fabricators and OEMs throughout North America for more than 15 years, delivering high-performance expanded polyolefin bead foam products that are easy to fabricate and fit into any product shipping or production foam component budget. Our experienced sales, design engineering, and distribution teams are dedicated to helping you find exactly what you need.

Customer Centric Approach

You are at the center of everything we do. Our highly specialized team listens to your needs, helping you find the right foam products for your application. We know what we have, you know what you need; it’s our job to make the connection and deliver the best foam planks for the job.

High-Quality, Affordable Materials

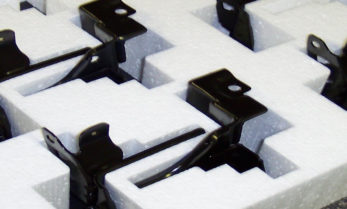

Our polyolefin molded foam planks are used extensively in hundreds of different applications. The autoclave reaction foaming process creates a very uniform cellular and bead-to-bead molded plank structure that protects your products. Fabricated packaging parts cut from our beaded foam planks will manage the input energy, then return to nearly 100% of the part’s original shape.

Short Lead Times

You get the products you need, when you need them! Our distribution centers in Tennessee, Indiana, Minnesota, and California are optimally located, allowing us to ship plank or sheet products anywhere in North America with high availability.

Experience You Can Count On

We have an entire library of technical data that can help you find the right foam for your application. And if you find yourself lost in the data, our friendly and experienced staff are available to pick up the phone and help you find what you need.

ARPLANK Foam Technology

ARPLANK EPE & EPP block-molded foam products offer strong performance for OEMs, fabricators, engineers & package designers who need:

- Very consistent cell, cell wall, density, and performance profiles with low built-in plank stresses

- High purity, non-toxic, and odorless materials that are resistant to mold and bacteria

- Engineered lighter-weight products that meet industrial, federal, military, and automotive specifications

- Identical energy management properties in all direction

- High static load limit capabilities

- Durability, resilience, and repetitive-strike energy management

- High heat resistance, cold impact resistance, and consistent thermal insulation properties

- Very low abrasion resistance and product surface protection

- Moisture, weather, and UV resistance

- Outstanding dimensional stability in demanding conditions

- High resistance to most chemicals, mineral oils, and solvents

- Exceptional buoyancy and flotation properties

All ARPLANK EPE and EPE materials are 100% recyclable and reusable. They are melt re-processable, made with FDA-approved resins, and meet REACH and RoHS requirements. They are also NAFTA compliant and classified as “Ozone Safe.” All products are expanded in a low-pressure autoclave using a chemically inert gas that does not emit any harmful CFC or HCFC gasses back into the environment.

More About ARPLANK Products

Learn more about our EPE and EPP molded foam planks, their fabrication capabilities, and their unique technical specifications.

Applications & Markets

Find your application or industry and see how EPE and EPP foam can be used to protect your high-value products or production components and parts.

Technical Documents

Access our complete library of foam data that includes water absorption rates, flammability performance, thermal conductivity, compressive set and creep, and so much more.

| Item | EPP | EPE | PE | XLPE |

|---|---|---|---|---|

| Product Examples | ARPRO | ARPAK | Extruded PE | Chemical Crosslink |

| Compression Strength | Excellent | Average | Average | Average |

| Durability | Good | Good | Good | Excellent |

| Elasticity | Good | Excellent | Excellent | Excellent |

| Flexibility | Good | Excellent | Excellent | Excellent |

| Tensile Strength | Excellent | Excellent | Excellent | Good |

| Chemical Resistance | Excellent | Excellent | Excellent | Excellent |

| Heat Resistance | Excellent | Average | Average | Poor |

| Thermal Insulation | Good | Good | Average | Average |

| Dimensional Stability | Excellent | Average | Average | Poor |

| Dynamic Cushion 1st Drop | Good | Good | Good | Good |

| Repetitive Dynamic Cushion | Excellent | Excellent | Good | Good |

| Contains HCFCs or VOCs | No | No | Yes | Yes |

| Amount of VOCs | N/A | N/A | Varies | Varies |