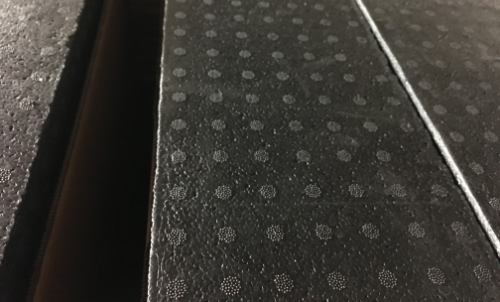

ARPLANK EPE and EPP Foam Planks

ARPLANK Direct is your source for expanded polyethylene (EPE) and expanded polypropylene (EPP) beaded foam planks. ARPLANK closed-cell foams are easy to fabricate and are widely used as protective packaging products across multiple industries. They are ideal for many applications, including:

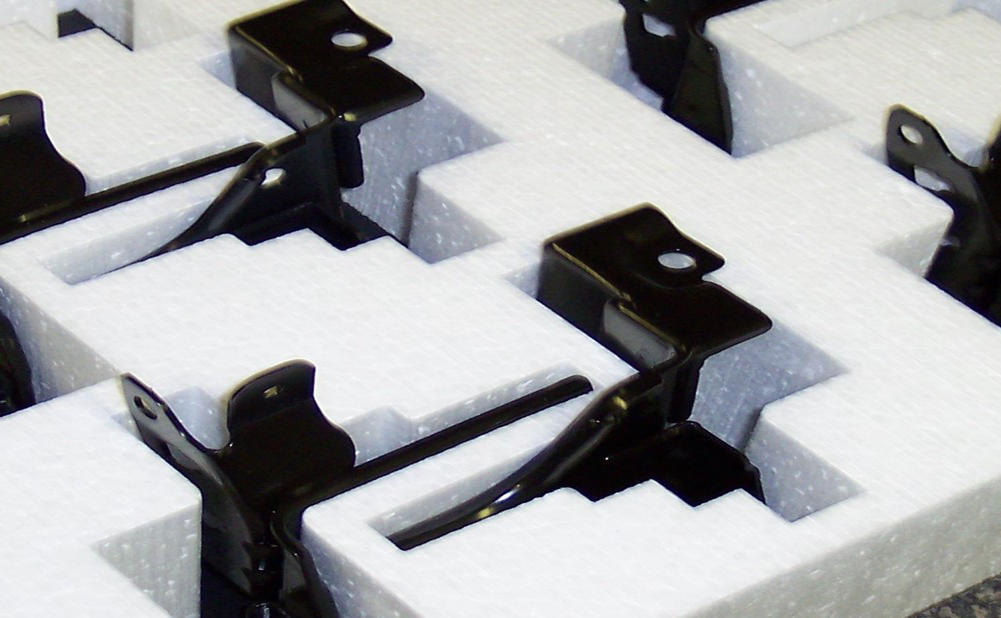

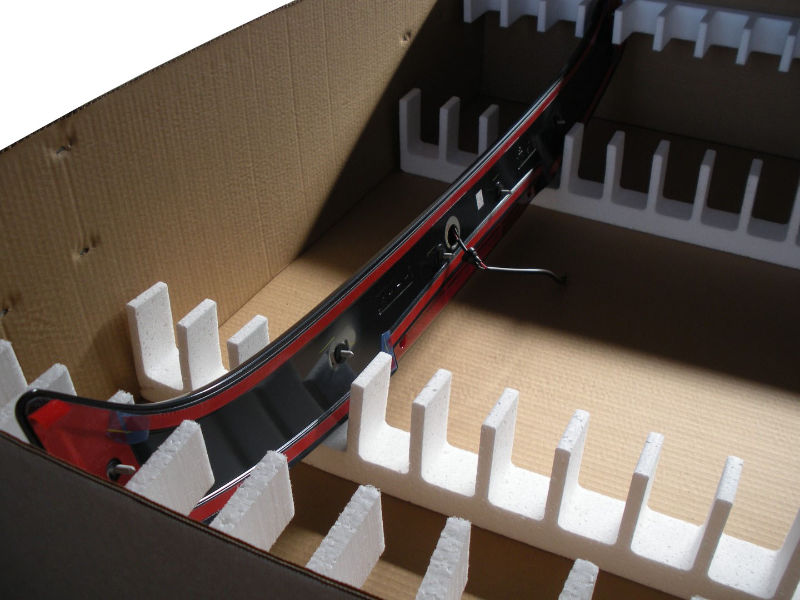

- Protective Packaging

- Certified Military and Coast Guard Grade Materials

- Class A compatible—Expendable and Returnable Dunnage

- Sports Field Shock Padding and Playground Underlayment

- Product Cushioning and Protection

- Blocking/Bracing, Crating and Floater/Cushion Pallets

- ESD and Anti-Static Protection

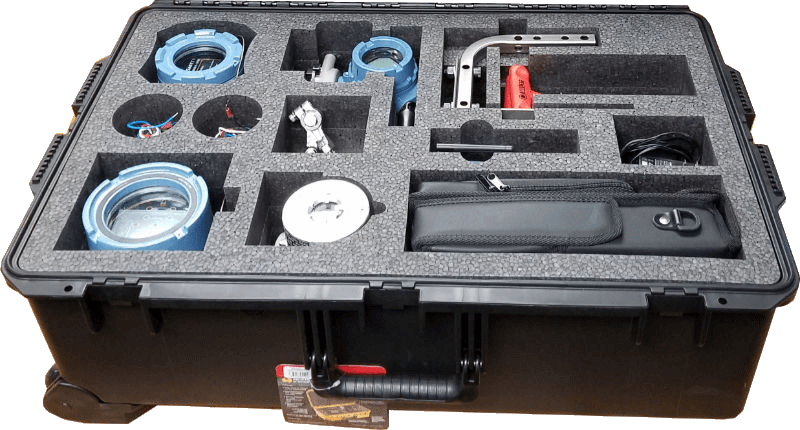

- Lightweight and rugged Case Inserts

- Returnable Containers for Thermal and Insulation Management

- Marine Flotation

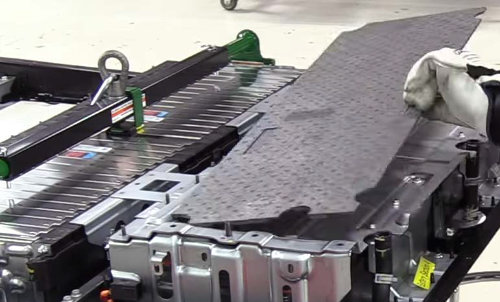

- Automotive Components

- Sound and Lighting equipment

ARPLANK foam planks are available in black and white colors and are sold as 6” x 48″ x 72″ planks with varying densities, from ultra-low to very stiff. We can also split our 6” planks into your desired sheet thickness.

| Material | Density, PCF | Plank Size | Thickness | Colors |

|---|---|---|---|---|

| ARPLANK EPE Expanded Polyethylene |

1.3, 1.5, 1.9, 2.3, 2.8, 4.6 | 48" x 72" | 6" | Black, White |

| ARPLANK EPE Expanded Polyethylene |

1.3, 1.5, 1.9, 2.3, 2.8 | 48" x 96" | 6" | Black, White |

| ARPLANK EPP Expanded Polypropylene |

1.3, 1.9, 2.8, 3.7 | 48" x 72" | 6" | Black, White |

EPP Application Solutions

- Best weight to strength ratio versus any PE foams

- Strain rate sensitive - best at higher drops and high impacts

- Best static loading management versus any PE or XLPE foams

- 212°F service temperature

- High vibration resistance and attenuation properties

EPE Application Solutions

- 50% better post cutting dimensional tolerances

- Broader loading range for the best dynamic cushioning

- Best impact recovery for multiple hit product protection

- Very low abrasion resistance - class A compatible

- Low compression set for better dimensional recovery

ARPAK Expanded Polyethylene (EPE) Foam Planks

ARPAK foam planks are made from high-quality expanded polyethylene (EPE) foam that is extremely resilient, allowing it to withstand multiple impacts without sustaining product damage. It offers strong resistance to chemicals, is lightweight, non-abrasive, and easy to fabricate, making it an outstanding material choice for custom protective packaging and many other applications.

ARPRO Expanded Polypropylene (EPP) Foam Planks

ARPRO (EPP) foam planks are both firm and lightweight, enabling it to outperform other (PE) foams in terms of strength-to-weight ratios. EPP is unique because it does better at higher impact speeds so it can protect heavy yet fragile parts from height drop requirements. EPP is strain rate sensitive and manages more energy the faster and higher the impact. EPP is also ideally suited for high static compressive loading up to 15 psi and high service temperatures up to 212F.

Specialty Foam Options

ARPLANK Direct supplies a variety of specialty foams in Anti-Static (AS) and Fire Retardant (FR) grades, including Grade B Anti-Stat and Grade C Fire Retardant materials. These materials have a longer shelf life than extruded PE foams, are available in multiple densities, and meet stringent military requirements as well as other industry test standards.

Why Arplank?

See What Makes Our EPE and EPP Foam a Step Above the Rest

| Item | EPP | EPE | PE | XLPE |

|---|---|---|---|---|

| Product Examples | ARPRO | ARPAK | Extruded PE | Chemical Crosslink |

| Compression Strength | Excellent | Average | Average | Average |

| Durability | Good | Good | Good | Excellent |

| Elasticity | Good | Excellent | Excellent | Excellent |

| Flexibility | Good | Excellent | Excellent | Excellent |

| Tensile Strength | Excellent | Excellent | Excellent | Good |

| Chemical Resistance | Excellent | Excellent | Excellent | Excellent |

| Heat Resistance | Excellent | Average | Average | Poor |

| Thermal Insulation | Good | Good | Average | Average |

| Dimensional Stability | Excellent | Average | Average | Poor |

| Dynamic Cushion 1st Drop | Good | Good | Good | Good |

| Repetitive Dynamic Cushion | Excellent | Excellent | Good | Good |

| Contains HCFCs or VOCs | No | No | Yes | Yes |

| Amount of VOCs | N/A | N/A | Varies | Varies |

Working with ARPLANK Foam

We Make Fabrication Easy

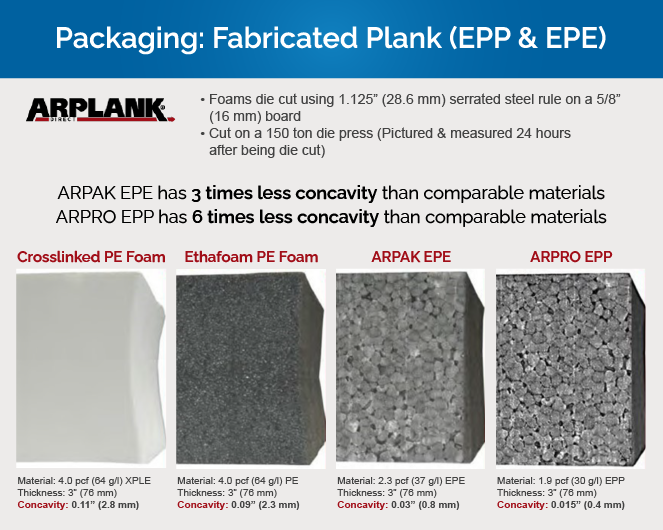

Packaging engineers, designers, and foam fabricators enjoy more material options and have broader design latitude when using steam chest molded EPE and EPP plank products. This is because the material’s high-performance base resins and steam chest molded plank manufacturing process produce very predictable physical properties.

If you need better packaging protection at the best value, ARPLANK EPE products outperform extruded Polyethylene (PE) or chemically crosslinked (XLPE) foams on a pound-for-pound basis. Because Molded EPE planks have identical properties in all impact and compression directions, they significantly reduce costly shipping damage in the toughest of material handling environments. Fabricated EPE molded foam plank materials result in highly predictable and consistent components every time they are produced.

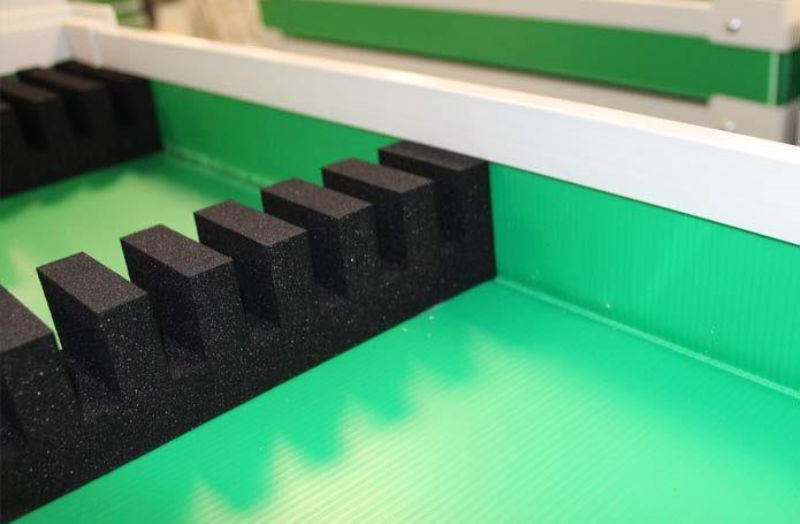

ARPLANK Foam is Easy to Fabricate with Standard Industry Cutting Equipment

- Horizontal Roll Splitters and Vacuum Skivers

- Manual and Automatic Steel Rule Die Presses

- Water Jet Machines

- CNC Routers

- Foam or Wood Saws

- Reciprocating Knife Tables/Flash Cutter

- All Heat Bonding and Adhesive Laminations

- Compression Molding

- Slabbing and Downcutting Hot Wire

- CNC Abrasive Wire Contour Cutting

The Ease of Fabricating with ARPLANK Foam

- Solid 6” planks for maximum yields, fewer layers, and tighter compound tolerances

- Significantly less concavity after die-cutting makes for tighter fitting parts

- Materials bond very well with hot air, hot melt glues, spray adhesives, PSA tapes, and contact cement

- Bead foams have more surface area than extruded PE, creating stronger bonds between laminated parts