Delivering Sustainable Performance

At ArPlank Direct, we’ve been a “green” supplier of sustainable, recyclable foams long before it was standard practice. Our mission has always been to deliver environmentally responsible, lighter weight foams that can be used for a variety of applications.

All ARPAK® EPE products can be recycled and reused. Foams can be collected, shredded, and either remolded or re-extruded (re-melted) into a “Repro-Material”. This material can then be sold as recycled PE or can be blended with virgin PE material to produce new ARPAK® EPE material.

RECYCLABLE FOAM THAT MEETS RIGID PERFORMANCE EXPECTATIONS

As a high-performance engineered material, ArPlank EPE & EPP provide a range of performance benefits for manufacturers and end users without sacrificing environmental considerations.

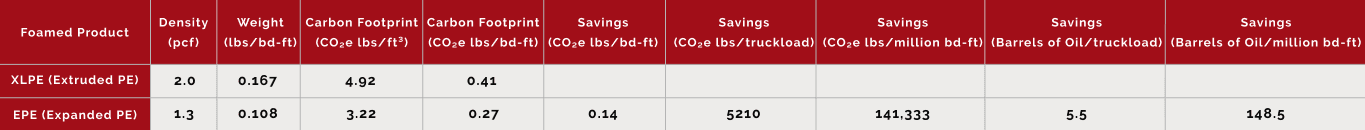

35% Less Carbon Footprint

Our engineered plastic resins allow for carbon source reduction by reducing the amount of polymer needed for protective packaging. ArPlank is chemically inert, made without VOC blowing agents, does not contain other ozone-depleting compounds and is low odor. It also does not contain any heavy metals, PFAS, and regular grade EPE and EPP do not contain halogen or brominated compounds. Our materials achieve a top ranking for Automotive Packaging Circularity per the Guidelines issued by the Supplier Partnership for the Environment. Designing with ArPlank products can achieve an immediate 35% reduction in carbon footprint.

Contributing to a Circular and Recyclable Foam Economy

EPE & EPP foams are not crosslinked, and can be melt-reprocessed back into the same product indefinitely. Each month, EPE alone keeps an estimated 94,000 pounds out of the automotive dunnage supply chain, reducing overall environmental impact and carbon footprint.

Reduce Your Costs

EPE and EPP foams are lighter materials that offer the same protection with potentially smaller cubic volume, all at a lower cost than XLPE. Their light weight can also help you reduce shipment dims and achieve a more favorable Shipment Class.

Made in the USA

All ArPlank resins and molded plank are proudly made in the USA. This eliminates the costs of importation while simultaneously reducing the in-bound transportation carbon footprint.

Protect Class “A” Surfaces

Our recyclable foams are non-abrasive, offering superior Class “A” surface protection for everything from vehicle parts to consumer electronics, home appliances and more.

Superior Protection with 40% Less Weight

Our recyclable foams help shippers and manufacturers achieve up to a 40% weight reduction in their foam content without sacrificing energy absorption, resilience, structure strength, dimensional stability and chemical and thermal resistance.

Designing with Arplank Foam

An Automotive Tier 1 Trim Manufacturer Made the Right Material Change

Using ARPLANK foam, they were able to package the same part size and achieve the same level of protection for their products, all while:

- Having a 1:1 part profile with 40% less final packaging mass

- Getting a 20% cost reduction

- Using a recyclable Class A foam